Smith & Wesson M&P Pro 9mm trigger job

The Smith and Wesson M&P9 Pro has become my favorite sidearm. It handles well, has great accuracy, and has great ergonomics. The only issue I have with it is the trigger. I have never been a fan of a hinged trigger safety design and I feel that it gives a mushy feeling as the safety is disengaged, followed by a long take up. Apex Tactical Specialties has come through again with an innovative product that not only makes a major improvement to the trigger, but to the action and safety as well. Up for review in this article is their Forward Set Sear & Trigger Kit.

Before I get into the installation, I want to mention a few things about Apex Tactical Specialties, and my experience with them. Apex Tactical Specialties has continuously impressed me with their innovative ideas and products. I currently use the Polymer Armorer Block and the Reset Assist Mechanism (RAM) in my M&P9 Pro, and both products are outstanding. The customer service is excellent, with clear lines of communication to help with general questions and technical support. In my opinion, this company combines superior products and great consumer support to provide a company image and reputation that sets the bar as to what a company model should look like. An interesting fact is that their products aren’t just used by responsible firearm owners and competition shooters. Many law enforcement agencies (around 20) also use the products they manufacture, including the Clackamas County Sheriffs Office and the Pittsburgh Port Authority.

-DISCLAIMER-

“Modifying the manufacture’s design of a firearm may void your warranty. This article is for informational purposes only, and is not meant to be a how-to guide. The purpose of this article is to review a specific product, and to show what may be involved during installation and function. You (the reader) are responsible for the safe handling, operation, and function of your firearm. You are also liable for any damage, injury, or accidental death that may result from incorrect work you may perform. WeLikeShooting.com, its writers, and staff recommend consulting a competent gunsmith or armorer prior to working on your own firearm.”

The Forward Set Sear and Trigger kit is available in polymer (as tested) for $129.95, and a hard anodized aluminum for $164.95. These kits function similarly to the S&W OEM parts and are designed to; provide a smoother trigger pull, reduce the amount of pre-travel and over-travel, and improve safety by removing the hinged trigger safety design and replacing it with a centrally located blade inside of the trigger. The caming surface on the sear is set forward, which advances the timing and provides a crisper break similar to a 1911. These kits will work in all caliber models of the M&P pistol (9mm, .40 S&W, .357 SIG, .45 ACP) except for the Shield. If you’re in the market for an improvement in the Shield’s trigger function, I would recommend the Shield Carry Kit.

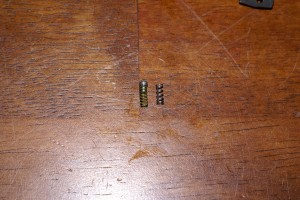

The kit contains a number of parts and a tool to assist in the re-installation of the rear sight. The included items are; trigger, sear, sear spring, striker block, striker block spring, Talon Tactical Tool (for re-installing the rear sight), slave pin, 4 lb. trigger return spring, 5.5 lb. trigger return spring (green), and a new spring for the RAM (if installed).

To begin, the M&P pistol was disassembled like it would be for cleaning. Always ensure the firearm is unloaded prior to take down, and any work is performed. The first parts replacement I did was the striker block. The new one in the kit is required for proper function since the timing is changed by the forward set sear. To do this, I used a small vice with 3″ jaws and soft inserts to protect the slide from getting marred. The slide was clamped, and the rear sight position was noted using a digital caliper (for exact replacement). The rear sight screw was removed, and the sight was driven out with a brass punch (non-marring) from left to right. As this was done, I was careful not to hit the cap on top of the striker block spring. After that, the spring and striker block were removed, and replaced with the new ones in the kit. The black spring cap was re-used, and held down by the Talon Tactical Tool while drifting the sight back into place. To complete this process, a function check was done several times by pushing forward on the striker (making sure it didn’t advance forward), and then depressing the striker block and pushing forward on the striker (to ensure that the striker will move freely).

The next part of the install is a little more involved, but straight forward. First, the take-down lever was removed by rotating it up and pulling out, then I removed the roll pins holding the trigger housing block and the sear housing block in place using the polymer armorer block. At this point, I believe it’s better to show you than explain this part of the kit installation. Here’s a look at what the process involved, and how it was done:

The forward set sear installation was an interesting process (in a good way). Apex Tactical Specialties has done a great job engineering this kit, and this is obvious when you compare the S&W sear to the new one. Here’s how the task was completed:

Now that the Forward Set Sear and Trigger Kit has been installed, how does it shoot? How does it feel? Does it make a difference and most importantly, does it work? I will say this……

“Un-freakin’ believable and wicked pissah!”

For those of you who don’t know, I’m in the North East just south of M.A. The phrases I just used are complimentary and with good reason. Apex Tactical Specialties has created a top-shelf product that not only performs, but well exceeded my expectations. Yes, I was expecting a better trigger break with reduced take-up and over travel. No, I wasn’t expecting it to feel similar to a 1911. It did. Not only that, but the increase in accuracy was amazing as well.

While this was a slightly advanced installation, the results (in my opinion) make the tested Polymer Forward Set Sear and Trigger kit is not only worth the purchase price, but the time it takes to put it in (about a half an hour). Once again, Apex Tactical Specialties has taken me by surprise with another reliable product that functions as advertised. Their online catalog contains a plethora of products for M&P pistols and other make/models as well. With more products in the works, I’m looking forward to continuing to do business with them, as they provide some of the best products I’ve used, and had the honor to test. My recommendation is; if you own a Smith and Wesson M&P pistol, this is your one-stop-shop. You won’t find better components anywhere else. Another great thing about this company is the customer service and installation support they provide. A perfect example of this is a walk through video for this kit with pistolsmith Randy Lee.

Thanks for reading,

-Rhody

You must be logged in to post a comment.